This is a Guest Blog by Mr. Ravin Saluja, director with STERLING AGRO INDUSTRIES LIMITED( Nova Dairy Products )

Ghee has been an important ingredient in Indian kitchens for years, used for everything from cooking to Ayurvedic remedies and herbs. Ghee enhances the flavour of food, but on the other hand, it also has various medicinal uses. It is used by almost everyone, nonetheless very few people are aware of its purity. Ghee adulteration is a common factor in the Dairy Industry. Thus, having the right information about genuine Ghee is important. The dairy industry continuously strives to use modern methods to identify and stop the adulteration of ghee. This article examines some of the latest techniques and tools used by dairy companies to guarantee the authenticity and safety of their ghee products.

Understanding Ghee Adulteration

Ghee is essentially clarified butter, produced by boiling unsalted butter to remove the water content and milk chunks. To boost profit margins, unscrupulous businesses are using unnatural ingredients, such as vegetable oils, animal fats, or even dangerous chemicals to abuse the authenticity of pure ghee. Ghee adulteration is negatively impacting on consumers’ health by reducing nutritional value of ghee.

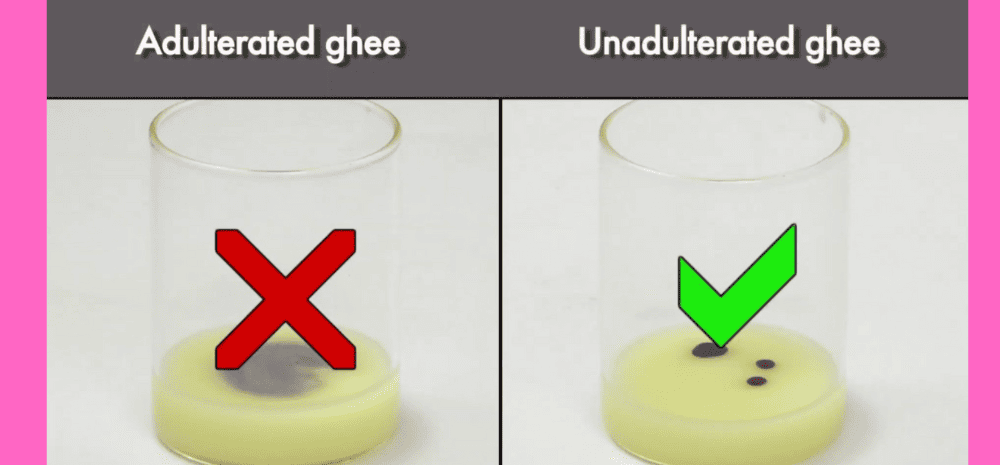

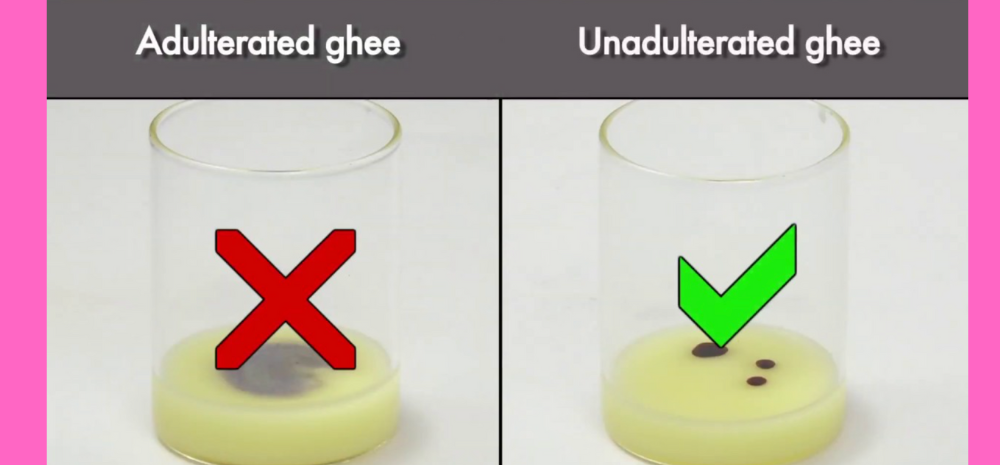

Traditional methods of detecting adulterated ghee have been used for generations by experienced individuals and small-scale producers. Few simple methods include, smell and taste, appearance, melting point or starch test. While these were helpful, but not as precise or reliable as modern analytical techniques.

Modern Methods of Detection

- Spectroscopy Techniques: Two methods such as Fourier-transform infrared (FTIR) and Nuclear magnetic resonance (NMR) can be used in detecting ghee adulteration. FTIR spectroscopy can identify particular molecular vibrations, which helps in differentiating between pure ghee and adulterated ghee. Whereas, NMR spectroscopy offers insights into the chemical composition of ghee and makes it possible to identify foreign substances.

- DNA Testing: Dairy companies may determine if ghee is made entirely from cow’s milk or a blend of several animal milks by analysing the DNA of milk samples. This method confirms the ghee’s authenticity and prevents it from fraud.

- Sensors and Machine Learning: Electronic tongues and noses for ghee quality testing are developed using innovative sensor technologies and machine learning algorithms. These sensors can quickly and efficiently distinguish adulterated ghee by detecting particular chemical elements or taste characteristics.

- Gas Chromatography: Gas Chromatography: The flammable components in ghee are separated and analysed using gas chromatography (GC). This method is very useful in identifying adulterants like vegetable oils or animal fats because they have different chemical signs. Even in small levels, GC is capable of correctly identifying these substances.

- Mass spectrometry: Liquid chromatography-mass spectrometry (LC-MS), is used to identify the presence of unwanted compounds, such as synthetic colourants and preservatives, which are present in adulteration, by analysing the mass-to-charge ratios of molecules.

Dairy companies are investing in innovative methods to identify and prevent adulteration as customer awareness and demand for premium ghee products. These companies can guarantee the reliability and security of their ghee products by using above mentioned innovative methods. By staying ahead of the adulteration trends and implementing these contemporary detection techniques, can preserve the consumers’ trust and purity of ghee.

Conclusion:

In conclusion, the adulteration of ghee in dairy companies is a severe problem that calls for ongoing focus and response. Together, authorities, companies, and customers can reduce the amount of adulterated ghee and guarantee that consumers have access to trustworthy and authentic dairy products. By staying informed, reading product labels carefully, and alerting the authorities when they see a product that seems suspicious, consumers play a significant role. Encouraging moral and authentic dairy companies that prioritize transparency and high-quality products also drives positive change in the dairy industry.