A wide range of dairy (milk) products, including yogurt, cheese, butter, paneer, and even ice cream, are produced by numerous dairy brands in India. All dairy products are regularly consumed nationwide and have long been standard household items. Private dairy companies in India made a sizable profit as a result.

In dairy farming, milk is produced over a long period of time. The milk is then made into a dairy product for sale (either on the farm or at a dairy plant, which is also referred to as a dairy). Cow barn farming has been practiced in numerous regions of Europe and Africa since the early Neolithic era, or roughly 7,000 B.C.

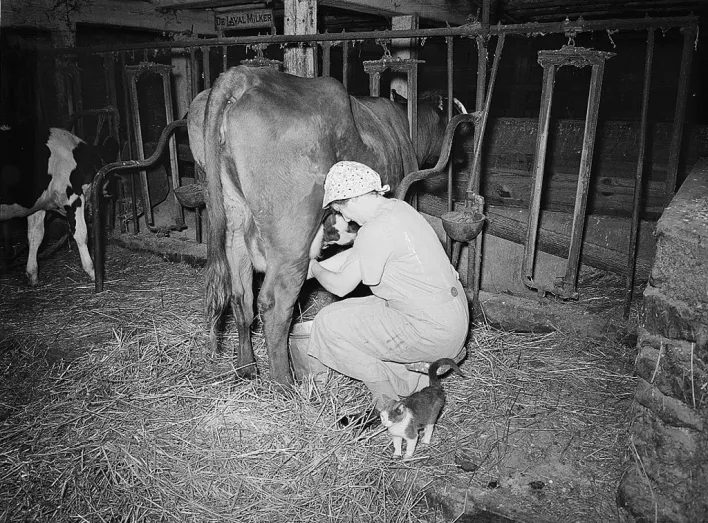

Before the 20th century, small farms milked their cows by hand. Inventions like rotary parlors, the milking pipeline, and automatic milking systems were first used by large dairy farms to milk their cows in the early 1900s; however, these systems weren’t widely accessible until the early 1990s.

Since the development of refrigeration technology in the late 1800s, milk storage methods have improved thanks to innovations like direct expansion refrigeration and the plate heat exchanger. Using these cooling techniques, pasteurized farms could stop milk from spoiling due to bacteria and humidity.

Many countries, including India, the United States, China, and New Zealand, which are major producers, exporters, and importers of milk globally, have sizable pasteurizing industries. Since the turn of the century, milk production has increased generally. The FAO estimates that 827,884,000 tons of milk were produced worldwide in 2017.

The way manure is discarded and the way methane gas pollutes the atmosphere are both clear signs of the intense tension surrounding the amount of waste the dairy industry generates. Environmental effects of the sector’s share of agricultural greenhouse gas emissions have also been considered. Several steps have been taken to lessen the amount of phosphorus dairy animals excrete in their waste.

Another subject of discussion has been the application of rBST. Animal rights activists typically oppose pasteurized farming because intensive animal farming is bad for the health of dairy cows.

History

The National Dairy Development Board (NDDB) of India gave the milk movement a significant boost in 1970 through a project known as “Operation Flood.” As a result, private industries started to understand how profitable selling dairy products could be. Tax incentives and subsidies were implemented to promote accessibility and increase milk consumption. As a result, the dairy sector in India went through one of its turning points and first historic moments.

Both in India and other countries, milk is now seen as a basic item in every household. The milk revolution, the country’s largest industry for almost a decade, boosts the economy by at least 4% annually. Although the production of milk advances more quickly than other agri-product sectors, the dairy industry consistently meets all of its developmental goals.

Dairy producers in India currently lead the global market for the production of milk and milk-based products, with an estimated 188 million MT of production from 2019 to 2020. The nation’s majority of farmers heavily rely on the revenue brought in by the market’s steady expansion. A third of the income in rural households comes from the direct employment of about 70 million farmers in the dairy industry.

Milk is one of the primary goods produced from domesticated animals in the area, followed by butter, cream, and milk powder. There are various types of milk, such as full cream (6%), standardized (4.5%), toned (3%), double toned (1.5), and skimmed (0.5%), depending on how much fat they contain. Milk needs to go through additional processing before it is prepared as a finished good.

Because milk consumption is more prevalent in India’s northwest than its northwest, it can be assumed that there is an uneven distribution of milk drinkers. In areas where those foods are consumed as well, milk sales are falling. The demand for milk products is significantly increased by citizens who are concerned about their health.

Milk sweets have become very popular since dairy products became a staple of the Indian supplementary diet. This nation produces well-known Indian sweets like rasgulla, milk peda, and kheer.

Cattle were milked in ancient Egypt. Around 12,000 years ago, cattle were bred for use as both a work and food animal. However, domestic cows were first used for milking in northwest Anatolia during the early Neolithic period in the seventh millennium B.C.

In later centuries, dairy farming started to spread to new parts of the globe. It started in Britain and Northern Europe in the fourth millennium B.C., Africa in the fifth millennium B.C., Eastern Europe in the sixth millennium B.C., and Eastern Europe in the fifth millennium B.C.

There have been more sizable farms that only produce milk over the past century or so. Large-scale dairy farming is the only viable option if a lot of milk is needed to produce pasteurized goods like cheese, butter, etc. that are more durable. Many milk-paying people don’t have any cows of their own. In the 1800s, von Thünen asserted that selling fresh milk was profitable within a 100-mile radius of a city.

The evolution of milk preservation methods

Sakhalin Island has a brand-new barn. Maintaining milk at cool temperatures has proven to be the most effective method for keeping it fresher for longer. Farms initially used windmills and well pumps to cool milk so that it would last longer before being transported to the neighborhood market. They were also used to provide water for the animals.

Underground water would be continuously pumped into a tub or vat to cool it. This chilly solution was added to tall, ten-gallon metal containers containing fresh milk, which is naturally warm. Before electricity and refrigeration, this was a common way to cool milk.

Refrigeration

When refrigeration was first invented, it was used to cool milk cans that had been manually filled. The cans were placed in a bath of cold water to remove the heat and keep them cool until they could be moved to a location for collection. As more automated methods of obtaining milk were developed, people stopped manually milking cows, and the milk can was replaced by a bulk milk cooler.

The original style of bulk milk cooler was ice banks. This tank had two walls, and coils for the evaporator and water were on the bottom and sides. The heat from the evaporator coils was removed by a tiny refrigeration compressor.

Over time, ice builds up around the rings, and when each pipe has about three inches of ice on it, the cooling system turns off. The milk agitator and the water circulation pump, which circulates water over the ice and the tank’s steel walls, are all that are required to cool the milk to below 5 degrees when milking begins.

This cooling method works well for smaller dairies, but as milking parlors grew bigger, it lost its effectiveness and couldn’t keep up with their cooling needs. Around the middle of the 1950s, the bulk milk cooler was the first device to use direct expansion refrigeration.

The milk is chilled for this type of cooling using an evaporator that is built right into the interior wall of the storage tank. Direct expansion has the ability to cool milk much more quickly than the previous method, which used ice banks. It is still the most common way for small to medium-sized businesses to cool their bulk tanks.

Another device that has significantly enhanced milk quality is the plate heat exchanger (PHE). The stainless steel plates that make up this device have minuscule gaps between them. Water is moved between the various teams of leaves while milk is moved between every other pair of scales to cool the milk. With this method of cooling milk, a significant amount of heat can be quickly removed from it, which reduces bacterial growth and enhances the milk. Most of the time, this device cools itself using groundwater.

However, dairy cows need to drink about 3 gallons of water for every gallon of milk they produce. They prefer drinking slightly warm water over cold groundwater as a result. As a result, PHEs can significantly improve milk quality, lower operating costs for the dairyman by making it easier for him to use his bulk milk cooler, and boost milk production by giving the cows access to clean, warm water.

The design of plate heat exchangers has changed as a result of an increase in the number of cows on American dairy farms. In order to increase milk production, a dairy farmer must increase the size of his milking barn to accommodate more cows. There is a lot more milk that needs to be moved around and cooled because the parlors have grown larger.

The increased milk production of today’s larger farms is too much for the direct expansion refrigeration systems on bulk milk coolers to handle. PHEs are typically used to quickly cool the milk to the right temperature before it enters the bulk milk tank (or a close approximation). Typically, groundwater is used to first cool the milk to a temperature of between 55 and 70 °F (13 and 21 °C).

A second (and occasionally third) section is then added to the PHE along with a mixture of pure chilled water and propylene glycol to remove any remaining heat. These chiller systems can be constructed with large evaporator surface areas and high chilled water flow rates for cooling large amounts of milk.

The top ten Dairy Companies in India for 2023 are:

We will talk about a few of these top dairy farmers whose unique business strategies have allowed them to handle milk for almost ten years now.

1. Amul

Unlike the other dairy businesses in India, AMUL has a well-established presence in the nation’s milk production industry dating back to 1964. They are thought to be India’s largest milk federation. Mr. Sardar Vallabhai Patel founded this company in an effort to do away with the middlemen system, which was steadily lowering the price farmers were paying for milk. To process milk for AMUL, more than 186 district cooperative unions have offered their services. It is obvious that other businesses think AMUL is doing something right because nearly every state in India has made an effort to imitate and copy the brand name, quality, and product.

2. Mother Dairy

Another participant to emerge from the “Operational Flood” is Mother Dairy, a well-known brand both domestically and internationally. They are a subsidiary of the NDDB as well (National Dairy Development Board). They have a strong presence in India and frequently export lucrative goods. Mother Dairy was only able to procure and produce for the NCR region, New Delhi, and the National Capital Region at the time the brand was first introduced. The company also makes ice cream and sweets on a large scale.

3. Kwality Limited

Kwality Ltd. is a company that deals with dairy products imported from India. India’s capital city of New Delhi serves as its headquarters. It was established in 1992. Kwality Ltd. manufactures dairy products in a range of formats. Items like milk, ghee, butter, milk powder, curd, lassi, paneer, ice cream, etc. are included in this category. Kwality Limited runs six facilities in the Indian states of Rajasthan, Uttar Pradesh, and Haryana.

Every day, 3.4 million liters of milk are produced in these facilities. This company employs people in factories in Gujarat, Bihar, Jharkhand, Haryana, Uttar Pradesh, and Rajasthan that turn out 3.4 million liters of milk every day. This company provides services to Gujarat, Bihar, Jharkhand, Orissa, Karnataka, and Andhra Pradesh. Actor Akshay Kumar has been named as its brand ambassador.

4. Orissa State Cooperative Milk Producer Federation

The Odisha State Cooperative Milk Producers Union was established in 1985. It ranks as India’s fourth-largest dairy corporation. It is also known as OMFED in D-2 Shaheed Nagar in Bhubaneshwar, Orissa. The state of Odisha’s Ministry of Fisheries, Animal Husbandry, and Dairy is the company’s owner. As part of Operation Flood-II of the National Dairy Development Board, OMFED was established using the Amul model.

It produces a wide range of products, such as milk and milk products, horticulture products, organic Kandhamal products, and cattle feed.

5. Andhra Pradesh Dairy Development Cooperative Federation

APDDCF, dairy companies, the top ten dairy companies in India, a dairy company, the biggest dairy, and the top ten dairy companies in India.

In order to advance dairy development, farmers founded the Andhra Pradesh Dairy Development Cooperative Federation Limited in 1981. It is organized cooperatively on three levels.

It charges reasonable prices for milk and items relating to milk. Additionally, it makes buttermilk, local paneer that hasn’t been cooked, dried-out sweets, and milk that has been sterilized and flavored. The capital of the Andhra Pradesh state, Hyderabad, serves as its headquarters. It also goes by the name APDDCF.

6. Karnataka Cooperative Milk Federation

Top 10 Dairy Companies in India, KMF, Biggest Dairy, Milk Company, Dairy Milk Company Karnataka Milk Federation, the sixth-largest dairy company in India, was established in 1974. The Indian Ministry of Fisheries, Animal Husbandry, and Dairy is its legitimate owner, and it is also known as KMF. The cooperative consists of different milk producers. In addition to milk, they also produce curd, ghee, butter, cheese, milk powder, sweets, chocolate, ice cream, frozen desserts, and other things.

7. KSE Ltd.

Kerala Solvent Extractions Ltd, now known as KSE Ltd, is a company that manufactures dairy products, cattle feed, and oil cake processing in Irinjalakkuda, Thrissur District, Kerala, India (extraction of oil from copra cake by the solvent extraction process and refining it to edible grade). The company was established on September 25, 1963, and in order to extract coconut oil from coconut oil cakes, it opened its first solvent extraction plant in Kerala in April 1972.

The company’s commercial operations officially began at this point. In 1976, the business built a facility to make ready-mixed cattle feed. Over the past three decades, KSE has advanced the field of solvent extraction from coconut oil cakes. Additionally, it is Kerala’s top supplier and producer of cattle feed. In the year 2000, KSE started buying, processing, and selling milk and milk products. In 2002, KSE started producing and distributing ice cream under the name “Vesta”.

Three divisions of the company exist the Cattle Feed Division, the Oil Cake Processing Division, and the Dairy Division, which deals with milk and milk-based goods like ice cream. The cattle feed division of KSE is responsible for producing and marketing cattle feed. The majority of KSE’s cattle feed is composed of de-oiled rice bran cake, maize, and de-oiled coconut cake. Some cottonseeds are added to the feed mixture to make it more balanced.

The company manufactures seven different kinds of cattle feed, including three in mash form and four in pellet form. Currently, KSE Ltd. primarily produces cattle feed; in FY2014–15, sales of cattle feed accounted for about 75% of its revenues. It reported 440,000 metric tonnes in sales during the fiscal years 2014 and 2015 and operates five modern cattle feed mills.

8. Dudhsagar Dairy

Mehsana District Co-operative Milk Producers Union Limited is frequently referred to as Dudhsagar Dairy. The foundation stone was laid in Anand on April 2, 1963, by Shri Mansinghbhai Prithviraj Patel, a state-level representative for the Gujarat Cooperative Milk Marketing Federation. Dudhsagar is home to Asia’s biggest dairy. In order to obtain milk from 450,000 milk producers and process, an average of 1.41 million kilograms of milk daily, a network of 1150 grams of milk cooperatives was established.

9. Dynamix Dairy

The headquarters of Dynamix Dairy Industries Limited are in Mumbai, Maharashtra, a region well-known for its dairy industry. In 1983, K.M. Goenka established it. The company exports goods to numerous other countries, including Singapore, Sri Lanka, Syria, and Turkey, in addition to the United Arab Emirates, the United States, Algeria, Bahrain, Bangladesh, Canada, China, Egypt, Iran, Korea, Kuwait, Lebanon, Malaysia, Morocco, Oman, the Philippines, Qatar, and Saudi Arabia.

This company makes ghee, curd, paneer, lassi, processed cheese, and natural cheese, among other dairy-related goods.

10. Milma

The brand name Milma is used to refer to the Kerala Co-operative Milk Marketing Federation or KCMMF. It all started in 1980 in Thiruvananthapuram, the capital of Kerala. This company has been approved by the Ministry of Fisheries, Animal Husbandry, and Dairy. Which cooperative society in Kerala is most likely among the best? It currently has 13 plants with a daily milk production capacity of 12.50 lakh liters. This dairy company is unique to the state of Kerala. Dudhsagar Dairy of India Gujarat is home to India’s biggest cooperative milk dairy.

2018-2023 Indian Dairy Industry Database

Over time, India has risen to become one of the world’s largest milk producers, with total milk production increasing from 122 million metric tons in 2010 to 171 million metric tons in 2017. Despite this, the majority of India’s dairy industry is still highly unorganized, with small and marginal dairy farmers dominating. The industry has attracted a number of private companies and investors due to its vast untapped potential.

Furthermore, the Indian government has been taking steps to develop the dairy sector by providing assistance to milk cooperatives and rural milk producers. Furthermore, the Indian economy’s sustained growth has resulted in increased consumer spending power, rapid urbanization, and changes in dietary patterns. With an increase in the working population, hectic lifestyles, and increased consumer health consciousness, there has been a shift toward healthy and ready-to-eat dairy products. A large number of affluent consumers who prefer value-added and premium dairy products have also contributed to the growth of the organized dairy sector.

With its Microsoft Excel-based report titled “Indian Dairy Industry Database 2018-2023,” IMARC Group, one of the world’s leading research and advisory firms, introduces a new and revolutionary way to understand and evaluate the dairy industry in India. This report examines the Indian dairy market analytically and statistically. The study, which used both desk-based and primary market research, examined the following aspects of the Indian dairy market.

Conclusion

Farming practices that involve long-term milk production are known as pasteurization. The milk is then processed at a dairy facility or on the farm to create dairy products for sale. Since the Neolithic era or roughly 7,000 B.C., pasteurized agriculture has been practiced. Pasteurized farming first appeared in Europe in the sixth millennium BC, and it quickly spread to other regions of the world. The key to preserving milk for longer has been cooler temperatures.

Farms have also used windmills and well pumps to chill milk and keep it cool. The primary use of direct expansion refrigeration was in milk coolers. Milk can be cooled using direct expansion much more quickly than with the current ice banks. American dairy farms now have more cows, which has also changed plate heat exchangers. Large farms currently produce so much milk that bulk milk coolers’ direct expansion refrigeration systems can’t keep up.

Before milk reaches the main milk tank, PHEs are frequently used to quickly cool it to the right temperature (or very close to it). Dairy products made in India are sold by Kwality Ltd. Milk, ghee, butter, milk powder, curd, lassi, paneer, ice cream, and other dairy products are all produced by Kwality Ltd. The company’s main office is located in Hyderabad, the capital of the Andhra Pradesh state. Karnataka Milk Federation has expanded since its establishment in 1974 to rank as the sixth-largest dairy company in India.

In 1983, M. Goenka founded Dynamix Dairy Industries Restricted. Aavin produces a variety of goods, including processed cheese, ghee, pure cheese, butter, curd, paneer, lassi, and others. The brand name Milma is used to refer to the Kerala Co-operative Milk Marketing Federation. It all started in 1980 in Thiruvananthapuram, the capital of Kerala. Of the daily milk purchases made by Aavin, only about 25 million liters are actually served as milk.

The top dairy companies in India are demonstrating how to properly market and sell a perishable goods like milk. Numerous other industries, both domestic and international, closely examine the business model and consider what makes it work. As a result, the dairy sector will grow by another 5% by 2023, retaining its position as a major contributor to our GDP.

Milk is one of the most important foods in any village, town, or prosperous city. Demand for cow’s milk is met with equal measures to improve milk collection, storage, and animal care, with a strong emphasis on the nutritional benefits. As a result, India’s dairy industry is expected to remain at the forefront of the global and domestic milk revolution.